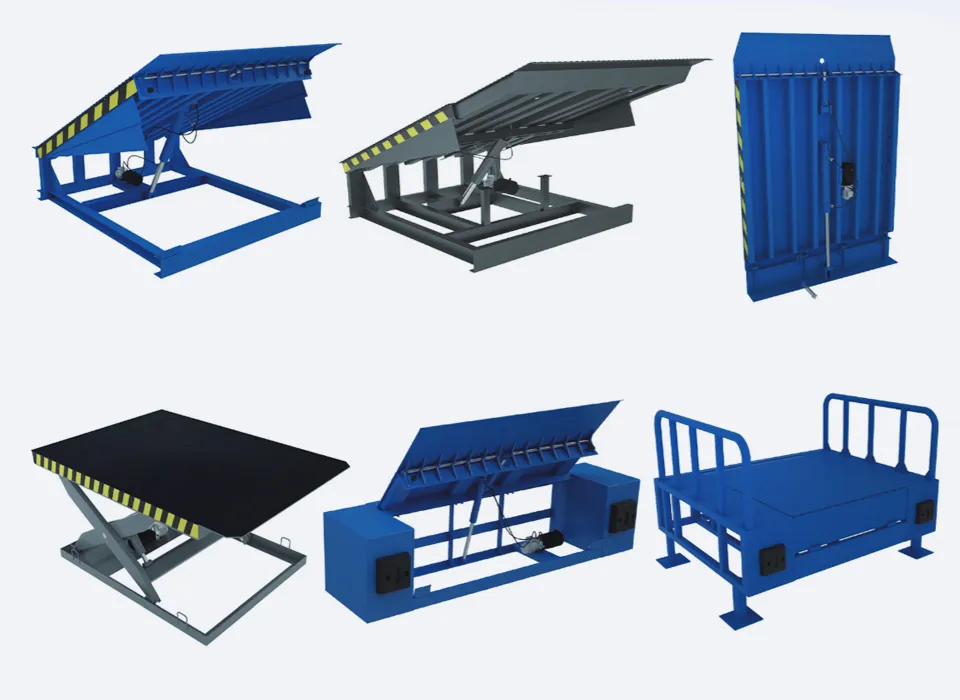

Dock Leveler Series

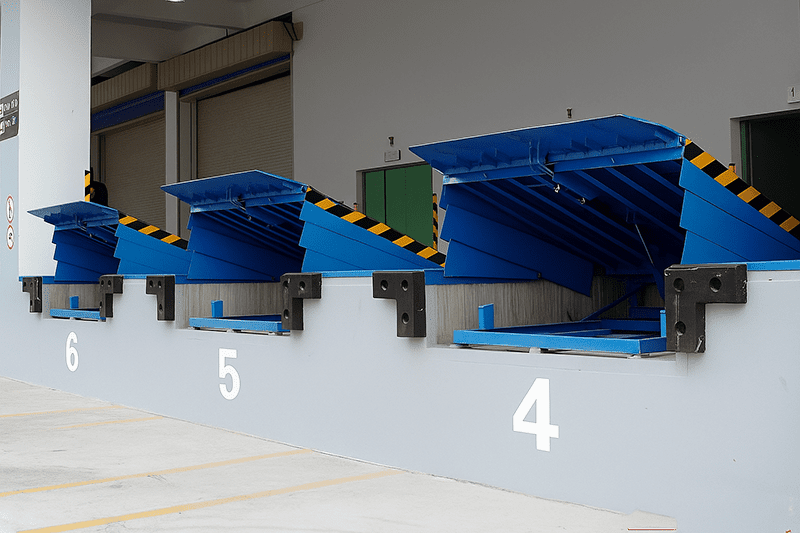

Dock leveler is designed to connect the warehouse dock to the truck body, effectively bridging the height difference and gaps between them. This allows goods to be moved into the truck more easily and efficiently.

Dock levelers not only improve loading and unloading efficiency but also reduce manual labor and enhance operational safety. Available in a variety of types—such as fixed, mobile, hydraulic, and telescopic lip designs—they can adapt to most warehouse layouts and operational requirements.

Whether for logistics parks, cold chain storage, manufacturing plants, or retail distribution centers, there’s always a dock leveler solution to match your needs.

Products from our high speed door series

Wide Range of Applications for Dock Leveler

Dock levelers are widely used in various logistics and warehouse facilities to bridge the height difference and gaps between the warehouse dock and truck body, ensuring efficient and safe loading operations. Common applications include:

Logistics Parks: Handle large volumes of goods with high-frequency loading.

Distribution Centers: Adapt to multiple truck types for fast loading and unloading.

Cold Chain Warehousing: Minimize cold air loss and maintain constant temperatures.

Manufacturing Plants: Improve efficiency in receiving raw materials and shipping finished goods.

Supermarket & Retail Warehouses: Streamline store replenishment and distribution.

Ports & Rail Freight Stations: Enable seamless connection between different transport modes.

Characteristics of Dock Leveler Series Products

A versatile dock leveler solution for improved efficiency and operational safety

High Efficiency:

Dock levelers effectively bridge the height and gap between the warehouse dock and truck body, ensuring smooth cargo transfer into or out of the truck. This seamless connection not only speeds up loading operations but also reduces labor costs, helping businesses improve overall logistics efficiency.

Multiple Types Available:

Available in fixed, mobile, hydraulic, and telescopic lip models, dock levelers can be customized according to warehouse structure, truck type, and operational frequency. Whether for large logistics hubs or smaller storage facilities, there is always a suitable solution.

Durable Construction:

Built with high-strength steel and premium hydraulic systems, the dock leveler structure is stable and capable of handling frequent, heavy-load operations. It performs reliably even under extreme cold, heat, or humid conditions.

Safety-Oriented Design:

Equipped with an anti-slip platform surface, safety support systems, and fall-prevention features, dock levelers minimize the risk of accidents during operation. This ensures the safety of workers while also preventing cargo damage during handling.

Durable Construction:

Thoughtfully designed for simple daily cleaning and maintenance, with easy-to-replace components. The low maintenance requirement helps extend service life, minimize downtime, and reduce repair costs, delivering higher return on investment.

Frequently Asked Questions

From features to selection – a complete Q&A guide for buying and using dock levelers. If you have additional questions or need personalized assistance, feel free to contact us anytime. Our team is committed to providing professional support and will respond within 24 hours.

What is the main purpose of a dock leveler?

The primary purpose of a dock leveler is to bridge the height and gap between the warehouse dock and the truck body, allowing goods to be moved smoothly and safely. It significantly improves loading efficiency, reduces labor costs, and minimizes the risk of cargo damage.

What are the common types of dock levelers?

Common types of dock levelers include hydraulic, telescopic lip, and edge types. Different types are suitable for different warehouse structures and loading and unloading needs. For example, hydraulic types are suitable for high-frequency operations, while mobile types are suitable for temporary or multi-point loading and unloading scenarios.

What is the load capacity of a dock leveler?

The load capacity depends on the specific model and design, typically ranging from 6 to 15 tons. We can provide customized solutions with different capacities based on your operational needs and cargo weight.

Is installing and maintaining a dock leveler complicated?

Dock levelers are usually installed by a professional team to ensure structural stability and safe use. Maintenance is relatively simple, involving regular inspections of the hydraulic system, anti-slip surface, and safety support components to ensure long-term reliable operation.

What is your MOQ?

1 set is a great start, but we look forward to larger orders and long-term cooperation with you.

Can my country be shipped?

Of course, we have experience working with clients in dozens of countries. Whether by land or sea, if we can reach your location, we can work with you.

Get a Quote

Let's start a friendly collaboration!

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Ultra-low price

- Excellent quality

- Thoughtful service

- Perfect after-sales service

- Reduce your costs

- Securing the working environment